Dr.aiR, a Customizable Air-Cushion Footwear Factory, Shortens Lead Times from 3 Months to 2 Weeks with Ragic

“We used to attribute our inability to deliver on time to production capacity issues, thinking that we needed more capacity and we continuously hired people. Now we realize that it's not a capacity problem at all; rather, it's a management issue! With Ragic, what used to require ten people to accomplish can now be achieved with just seven.”

“Previously, after 3 to 5 months of production, shoes could disappear without a trace! Now, within one or two weeks, we can always ship out and inform customers of the progress. Customer service and production efficiency have both improved drastically.”

"Only when the person in charge of the company jumps in hands-on operations and strategic thinking can they design a database that truly meets the needs.This approach shortens the digital transformation process, resulting in substantial and predictable returns.”

| Organization | Dr.aiR Air Cushion Shoes  |

| Industry | Footwear Manufacturing |

| Problem to solve | To create a comprehensive cycle system from production to order tracking tailored to their highly customizable production process |

| Benefits of implementation | Reduced lead times, elimination of missing orders, increased production capacity, enhanced efficiency in customer service |

| Plan | Professional |

| Applications | Utilized daily for production, inventory management, order tracking, and customer service |

| Scale of use | Small-scale factory of 15-20 staff, managing customizable air-cushion shoes with a shipment volume reaching thousands of pairs |

| Why does Dr.aiR like Ragic? | Multiple Versions, Ragic App for enhanced mobility, QR codes, shallow learning curve, high mobility, responsive customer service |

"We've been waiting far too long for your shipment!”

The atmosphere in the conference room was tense as the customer clearly came prepared, laying out data, they said: “After years of partnership, the chairman favors your product, consistently placing orders for hundreds of pairs each month. However, your average lead time of three to five months, with occasional mistakes and disappearing shoes in between, has led to a stream of negative feedback from our sales team.”

This is how Dr.aiR's day looked before their transformation with Ragic: lead times were behind schedule, orders were missing and incorrect, there was no tracking process for customers to follow up on their orders, production staff were overloaded, customer service calls didn't stop, and uncountable complaints from corporate customers, with threats of partnership termination.

Dr. aiR Therapeutic Air Cushion

Don’t get it wrong, even in its chaotic era, Dr.aiR is not some sort of low quality shoes. On the contrary, the founder of the company behind Dr.aiR, the father of Ms. Huang, with his patented technologies, is one of Taiwan's earliest air cushion manufacturers. He was also a technical consultant for renowned athletic shoe brands like Nike and Rebook.

Dr.aiR's air cushion fully customized shoes

The key to the superiority of Dr.aiR's comfortable air lies in its 3D structure. Unlike traditional shoes with flat cushioning, Dr. aiR's air cushions are designed to fit your feet with a molded, three-dimensional structure, providing stable support and even pressure distribution. Moreover, this innovative technology allows for customization based on individual needs, adjusting the air cushion according to the wearer's walking sytle, posture, and gait.

“Many people with foot problems always treat the problem rather than the root cause. When we think about foot problems like hallux valgus, plantar fasciitis, and scoliosis, they are actually related to walking posture. Our approach is to use air cushions to adjust shoes, altering the wearer's walking balance and correcting their gait." The manager of Dr.aiR, Ms. Huang, explained how a customizable air cushion can address foot problems.

Take hallux valgus, better known as a bunion, for example. Ms. Huang explained that this condition occurs when the center of gravity is pushed forward and inward during walking, putting pressure on the base of the big toe. Dr. aiR can adjust and reinforce the inner support, shifting the center of gravity from forward-leaning to rearward, thus alleviating the forward pressure on the center of gravity. As thumb pressure is reduced, the body begins to repair naturally, leading to the resolution of many customers' thumb swelling and pain issues.

This miraculous and dynamic "therapy" is precisely why major clients are enamored with Dr. aiR. One of Dr.aiR’s corporate customers said that after wearing their custom air cushion shoes, their chairman not only walks and runs comfortably but also finds it difficult to go back to wearing other shoes.

From Outsourcing to In-house Production Challenges

Behind this unique technology and customizable capabilities, Dr.aiR has always been suffering from inventory management problems in their production side.

In its early days, Dr. aiR operated under an outsourcing model: its core air cushion soles were made in-house, while shoe uppers were outsourced to other factories. These uppers were then brought back to the factory to be combined with the soles, creating finished shoes. So when an order is placed, they would retrieve the correct size, produce the customized air cushion, and match it together as a finished shoe to ship to the customers.

However, the minimum order quantity from suppliers didn’t work in Dr.aiR’s favor, because somehow they were still a small scale company. With big MOQ, they needed to accumulate stock, making it tougher for quality control.

With this problem, they decided to switch to a fully in-house, on-demand production model two years ago. After receiving orders, Dr.aiR now customizes fabric, prints designated patterns on the uppers, sews, matches, attaches the soles, adjusts, and ships the products entirely in-house. This approach offers greater control over inventory and customized product quality.

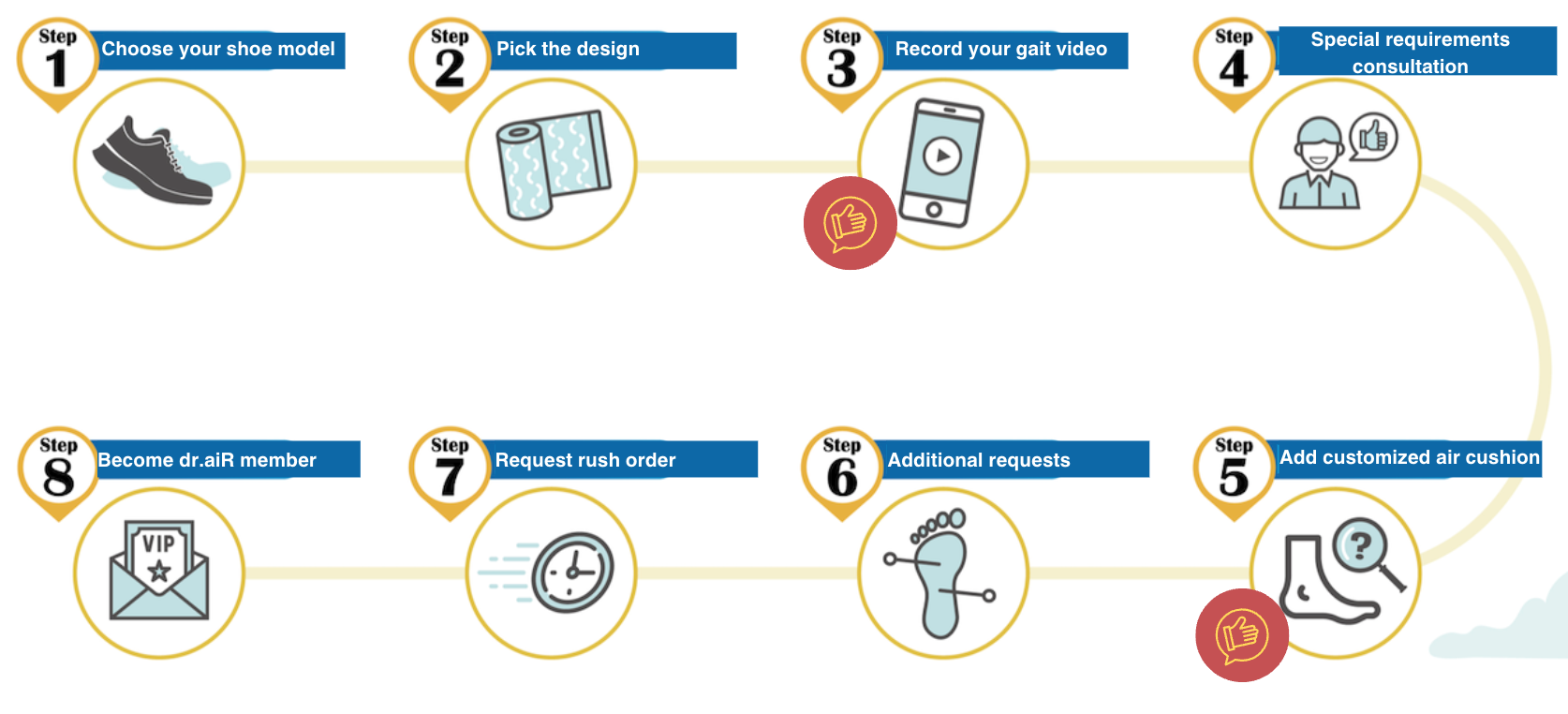

Dr.aiR order process

"We were actually an air cushion factory, not a shoe factory, we didn't know how to make shoes."

When deciding to make everything in-house, this transformation scrapped the old production model and started anew. Instead of simply manufacturing air cushions, they now produce entire shoes. The process shifted from batch production for resale to fully customized on-demand production. This crisis served as a turning point; Dr.aiR managed to completely develop its own customized air cushion shoes, even though it inevitably involved painful trial and error. One of the issues encountered was the inability to deliver goods on time, as pointed out by major clients during meetings.

"Each of our orders is highly customized. When an order is made, each pair isn't just customized in terms of upper printing and gait adjustments; they may also have different specifications. Even with a small production line, we have to balance quality, quantity, and efficiency. Additionally, we must be ready to provide updates on production progress at any time. This is highly challenging."

With the adoption of the new custom order model, it's imperative to have the capability to track the current stage of production for each pair of shoes to monitor progress effectively. In the past, such tracking wasn't necessary for mass production, and there was a lack of supporting management systems, resulting in confusion during the transition period.

"We kept records of orders, but once they entered the factory, we lost track of their progress until they were ready to be shipped. There were instances where customers would call and express their frustration, even two months after placing an order, and we still wouldn't have any updates, forcing us to contact the factory for information. It was quite common to discover that an order hadn't been processed at all, or that the factory had failed to report back, resulting in the shoes being left idle and the entire order left untouched."

ERP Is Too Expensive, Excel Is Not Suitable, They Finally Found Ragic

Ms. Huang started with looking for a suitable order management tool to deal with this problem. She looked back at the ERP system Dr.aiR’s parent company has used for over a decade, capable of recording customer data, sales records, and managing inventory quantities. However, they had purchased the most basic version, which couldn't track every stage of an order from order confirmation, all stages of production, to shipment. Investing in an advanced version or customizing the system for this transformation was too complex and costly.

At that time, even the representative from the ERP company suggested to them: "Since your company isn't large in scale, to save money, just use Excel." But Ms. Huang believes that although the company wasn't large, it still had hundreds or even thousands of orders to manage, requiring dynamic tracking that can not be done with Excel.

"Is there any tool like Excel but more powerful?" This was the query Ms. Huang entered into her Google search, leading her to discover Ragic. Packaged like an Excel sheet but with powerful database capabilities, Ragic seemed to be what they were looking for, offering a solution for small to medium-sized companies unwilling to invest heavily in customized ERP systems or hire developers to build a system from scratch, as Ragic could construct a customized system without the need for coding. Numerous case studies showcasing how other companies managed their sales orders with Ragic convinced Ms. Huang to give it a try.

At the beginning of her journey with Ragic, Ms. Huang didn't initiate a major overhaul of the entire company's workflow. Instead, she began by reaching out to the production staff at the factory in southern Taiwan to understand their system requirements. She then proceeded to import the company's existing sales order information into Ragic and started preliminary sheet design. Over the course of a year, she persistently followed this process, gradually building and refining the workflow as the company expanded.

"Truth be told, your customer support team is amazing. Over the past year, they've been incredibly efficient and effective. They've guided me from being someone who had no understanding of databases to someone capable of designing the sheets I need." Ms. Huang remarked.

Learning Ragic has instilled in her a method of thinking based on database logic. She used to be hesitant to visit the factory in the south, thinking, "Why should I go there? I don't understand what's going on or how to fix it anyway." However, with Ragic, she's been prompted to adopt a new mindset. When she visits the factory now, she approaches it from a database perspective, asking herself, "Is this production process seamless? How can it be integrated with the database?"

3-Month Transformation: Enhanced Workflow, Delighted Customers

When Ms. Huang, based in the northern office, made the decision to implement Ragic at the factory, she started frequenting the southern factory and officially introduced Ragic. She mandated that production staff input all order details, ensuring data accuracy and consistency. Personally involved in production, she urged the production staff to integrate Ragic into their production processes.

Looking back, it was a stressful moment for Ms. Huang. Production delays and product quality issues were already straining the company's reputation. She worried if the new system she introduced would worsen production delays or solve them. Thankfully, after three months, her doubts disappeared.

“Before returning to the south, we had hundreds, nearly thousands of unfinished orders. Within three months, we not only completed production on these orders but also implemented a system allowing us to scan QR codes with our mobile phones to track each order's progress in real-time.”

Reflecting on the meeting when the key customer was frustrated over delayed orders and quality issues, after the implementation of Ragic, Ms. Huang witnessed positive outcomes, and confident that this complaints had been resolved.

"After updating them on our situation prior to February, which was quite dire, I emphasized the transformative impact of our new database system. Now, with the same volume of orders, we can fulfill them within a two-week timeframe. This shifted their perspective entirely. Initially, the major client was considering halting all cooperation. However, upon hearing our explanation, they began sending representatives to our office biweekly to witness our progress firsthand."

"After witnessing the transformation, we recognized that Dr.aiR not only resolved order management issues but also stabilized their supply chain, ensuring transparency throughout the production process. Ms. Huang also utilizes Ragic to train our customer service team on accessing Dr. aiR’s system, enabling us to track shoe progress in real-time." said one of the representatives.

As a result, cooperation between the two parties resumed, and each sales district of this corporate customer now remotely utilizes the Ragic system for order inquiries and modifications.

At the beginning, Ms. Huang's father was reluctant to implement another system alongside their existing ERP. But witnessing the rapid turnaround firsthand left him speechless. “It showed that the changes I initiated upon returning to the south had a significant impact.” Ms. Huang added.

Production Capacity Issue Revealed as Management Problem

Ms. Huang highlighted that after implementing Ragic, they not only eliminated the issue of missing shoes but also drastically reduced their shipping time from 2-3 months to less than two weeks, provided there are sufficient materials available.

“We used to attribute our inability to deliver on time to production capacity issues, believing that we needed more capacity and continuously hiring people. Now we realize that it's not a capacity problem at all; rather, it's a management issue from start to finish! With Ragic, what used to require ten people to accomplish can now be achieved with just seven.”

For Ms. Huang, digitizing processes is important to enhance efficiency. She recognized that without the right tools, scaling would be challenging. Fortunately, in today's tech-driven era, implementation costs are relatively low, presenting an opportunity for growth through effective process management.

What Does Dr.aiR Manage With Ragic?

Ms. Huang used the multiple version, QR code, and Ragic App, to complement her Production Management Template by Ragic (BOM Explosion Sheet), to create an order tracking management system that can be used seamlessly by every member of the company. Here are some of Dr. aiR’s Ragic design and application methods:

1. Multiple Versions for One-Stop Tracking Sales Order to Production

In business models where products are made before being sold, managing orders and inventory involves recording inventory quantities for each specification and deducting inventory upon shipment. Detailed logging of each individual product is often unnecessary.

This is the biggest difference with the customized order business model like Dr. aiR, where each order is unique and it is necessary to track each order's production progress. Dr. aiR uses Multiple Versions of sheets, where several sheets share the same set of data, to accommodate their Work Order Sheet needs in various stages of production and inspection, such as "Inspection Process", "Incoming and Outgoing Stock", "Order Progress Inquiry", "Mobile Version", etc. These sheets share the same set of data but are tailored to each specific stage of production. This way, inspection staff and supervisors, production staff, and shipment staff don't need to crowd one sheet with all their information. They can get to see only what they really need. But still, all their data is synchronized. When one sheet is updated, all other multiple versions of this sheet will also be updated.

2. Efficient Raw Material Calculation with BOM Explosion Sheet in Production Management Template

Previously, the production staff had to manually calculate the quantity of materials needed for each pair of customized shoes, often leading to errors. When Ms. Huang discussed implementing Ragic with them, a major question they raised was, "Is there a way to avoid manual material cost calculations?"

Ms. Huang fine-tuned the Production Management Template in Ragic. By utilizing the BOM Explosion feature in the Work Order Sheet, with just one click, this feature automatically calculates the raw materials required for each pair of shoes, significantly reducing the chance of miscalculations.

Sample data of Dr.aiR's Work Order Sheet

They also leverage Ragic's reporting feature. Previously, they had to manually calculate data in the Order Picking Sheet and Work Order using Excel. Now, they simply enter the order delivery date to generate the output, reducing the error rate in manual calculations, and if there are any errors in the report content, they can be traced and corrected immediately.

3. QR Codes: User-Friendly Solution for Elderly Staff

How can all production staff consistently update work order progress after each production stage? And how can elderly staff, unfamiliar with technology, easily follow this process? To maintain a clear overview and transparency for customers to know the production progress, it's crucial for all production staff to report progress at each stage.

Ms. Huang's solution simplifies this process by enabling staff to use their mobile phones, which are easier to operate than PCs. All the production staff has to do is scan the QR code and click on the date to update a production stage they completed. This simple method allows easy adoption even for staff over 60 years old.

Each order receives a label generated by Ragic's label maker, containing a barcode with essential details like order ID, shoe type, model, and size. These labels are attached to each shoe in the production. Staff can then scan these labels using the Ragic mobile app to access specific order details, update production progress, check previous stages, and approve orders.

QR-code scanning process in Dr.aiR's factory

Ms.Huang also designed Multiple Versions of the Work Order sheet so it is more simple to be utilized in Ragic mobile app, which only consist of necessary information to update the production progress such as Work Order Status, Execution Date, Production Stage (Such as uppers, outsole fitting date, etc).

Then, she distributed old smartphones to employees with only the Ragic app installed, and explained: "Simply touch this app to open the sheet. When an order comes in, scan the QR code, enter the date, and you're done."

Sample of QR code usage

Of course, initially, the elderly staff resisted, fearing the new technology would be too complicated. However, it was actually just two simple steps. Most of them learned it in under 10 minutes. As they grew accustomed to it, Ms. Huang encouraged them to use more advanced features, such as filling in the Remarks Field to note any production progress issues. "If you can type messages on WhatsApp every day, you can easily type in a few words like 'Sole problem' right?" Ms. Huang remarked to one of the elderly staff.

On the other hand, mobile apps also make information accessible from anywhere. Previously, they had to check information on the computer and then visit the factory to verify it. Now, they only need to take their mobile phone to the factory, scan the barcode, and manage orders, inventory, and shipments seamlessly, eliminating the need to run back and forth between locations.

Ms. Huang said that mobility that is offered by Ragic mobile app is a major contributor to the transformation of the entire company, because only by thinking not in terms of desktop computers, but in terms of mobile phones, people of all ages can easily adapt to changes in company processes and job requirements. Today, everyone in the company relies on Ragic for their daily operations.

"What's even better is that, except for the Ragic licenses, which is an additional purchase, all we needed were existing mobile phones and label machines. We're using old equipment to do innovative things!"

4. Transparent Progress Tracking, Anytime, Anywhere

With the mobile app, frontline customer service and store sales no longer need to make phone calls or visit the factory to inquire about the progress requested by customers. They can get their results by checking their mobile phones within 10 seconds.

Dr. aiR also grants B2B customers access to their Ragic system, streamlining order progress tracking and replacing chaotic email and phone communications, as well as outdated Excel files.

This shift is Dr. aiR's key to transition from reactive to proactive customer service by actively monitoring production progress. With the ability to identify stagnant orders, they can investigate and address issues before they escalate into customer complaints.

5. The Flexibility to Improve

Ms. Huang expressed her desire to further enhance company processes after witnessing the positive impact of implementing Ragic. With production now streamlined, she aims to optimize the customer relationship management system by integrating customer information with work orders for seamless tracking. The ultimate goal is to increase production capacity while maintaining the same workforce through efficient management.

Ragic's high flexibility and scalability prove invaluable in this pursuit. Small adjustments can be made easily, and major modifications don't require lengthy quotations and evaluations. The workflow structure can be continuously refined to optimize operations.

“Our database design process wasn't completed in one step. It's more like building a highway, where elements are added incrementally. Sometimes, an entire sheet needs to be revised and reworked. Fortunately, with the sheet copy function, data loss is prevented."

“I'm not sure how many sheets we've designed and discarded in a year, but everything is now configured for a more comprehensive order management process, enabling us to manage both B2C and B2B orders, as well as customer service and production seamlessly. Everything is systematically sequenced, integrated, and executed.”

The One in Charge of the Workflow Is Best Suited to Build the Database

According to Ms. Huang, after over a year of learning and implementing Ragic, she realized that those responsible for the company's operations are best suited to design a database that truly meets their needs.

Initially, lacking a computer background, she considered hiring a Ragic Partner to assist in building the database. However, during interactions with production staff at the factory, she came to the realization that she was uniquely positioned to undertake this task. No one else would invest the time to truly understand the production process and industry requirements as she would.

This occurs because the leader's role is influential enough to unite subordinates in integrating the new process, thereby reducing communication time and enhancing efficiency within the work hierarchy. Moreover, they can promptly test, correct, and optimize processes in a short span. This new approach has unveiled numerous possibilities for Dr. aiR's future.

カテゴリ: Case Studies > Manufacturing