If you sell products like clothes, shoes, and accessories, they're most likely divided into different designs, and each design may have multiple colors and size options. You're probably wondering whether you should "create one record for each design" or "create separate records into SKUs for different colors and sizes under a single design" when managing inventory.

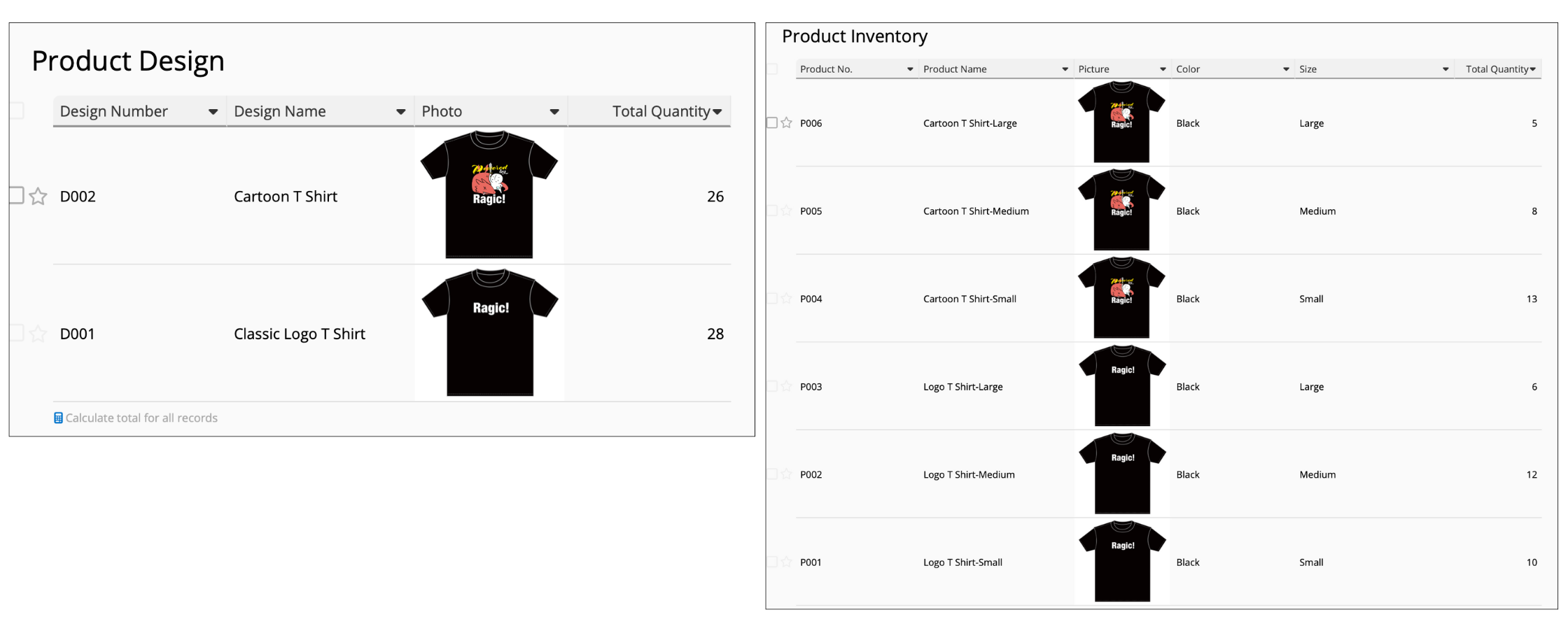

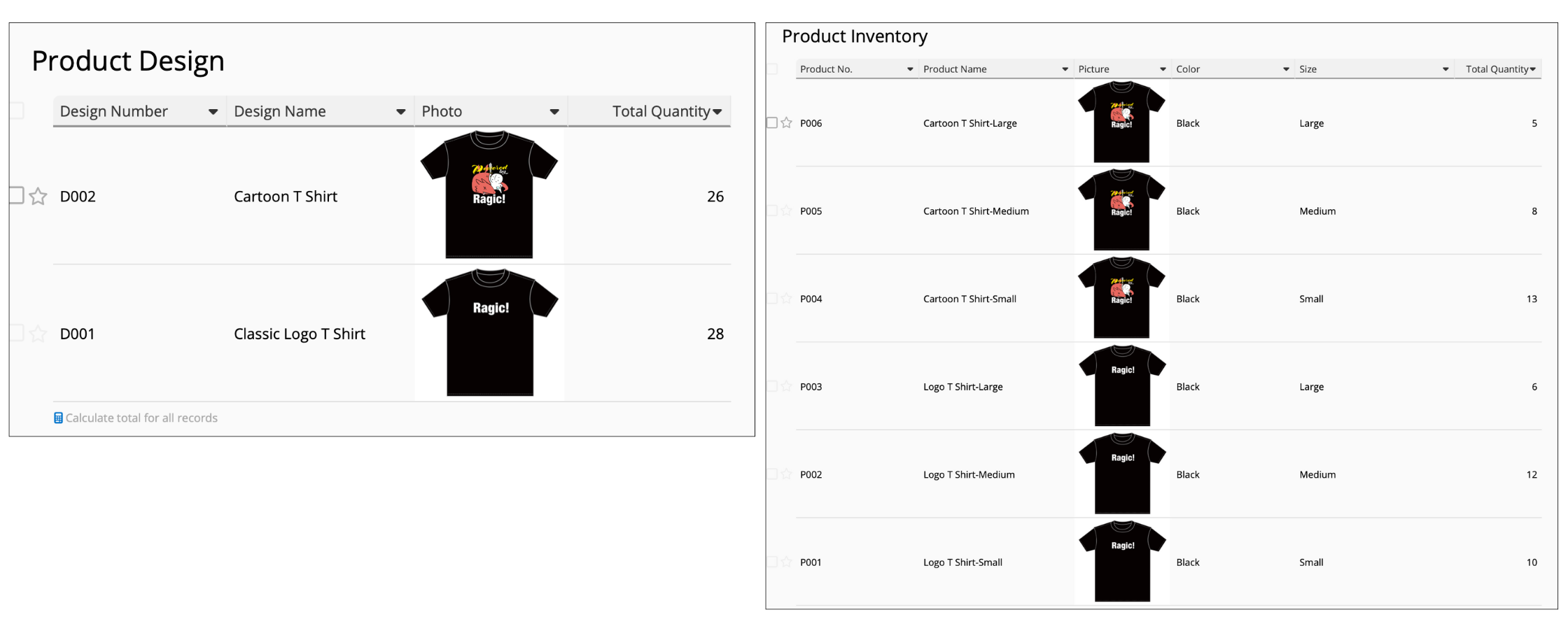

For example, let's say the T-shirts you are selling are subdivided into 2 designs: "Cartoon Design" and "Classic Logo Design," and each design has multiple sizes: Small, Medium, and Large. Should you create only 2 records for each design (left side of the photo below) or create 6 records, taking different designs and sizes into consideration (right side of the photo below)? These 6 records are broken down as: Cartoon Design Small, Classic Logo Design Small, Cartoon Design Medium, Classic Logo Design Medium, etc.

If this sounds like a similar situation your business faces, we recommend "separating" the records as shown in the right photo! In this article, we'll explain why it would be more convenient to separate the records into SKUs during inventory management, how this can help when entering orders and deducting inventory, and how you can analyze inventory of a single design on Ragic.

When conducting inventory and data management, we should divide the data into the "smallest unit" in order to distinguish these differences, according to management needs. If distinguishing the differences is necessary, we must establish them as separate, independent data. This is what we often refer to as "SKU," the smallest unit of a product that can be sold from inventory, purchased, or added to inventory.

What's the difference? Let's use the previous photo as an example:

If we were to calculate the number of inventory left, the Small, Medium, and Large sizes are different for every design. Hence, it is not enough to create a record that only distinguishes between designs, as shown on the left. It would be more meaningful and informative to calculate the quantity separately according to each design and size, as done in the photo on the right.

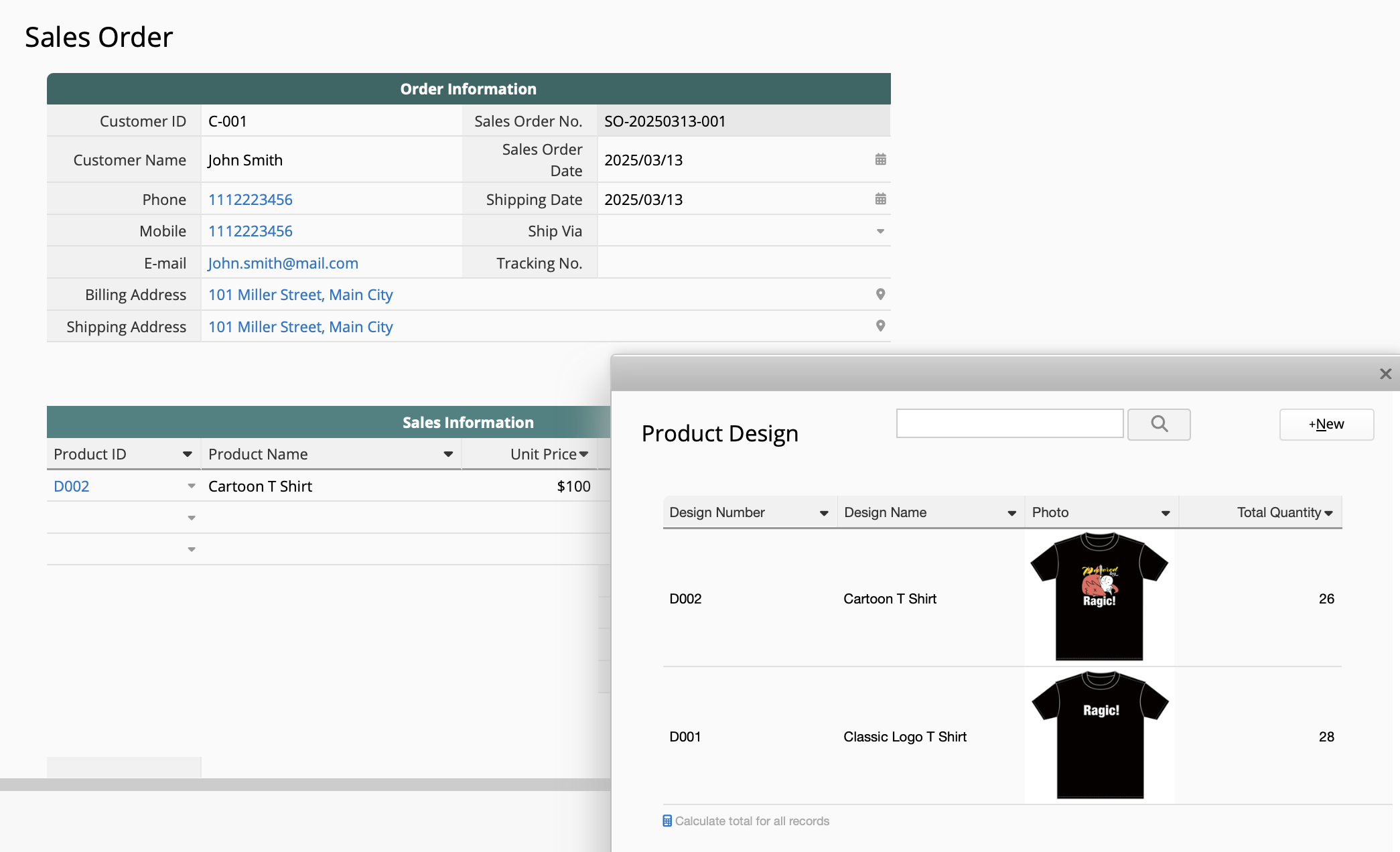

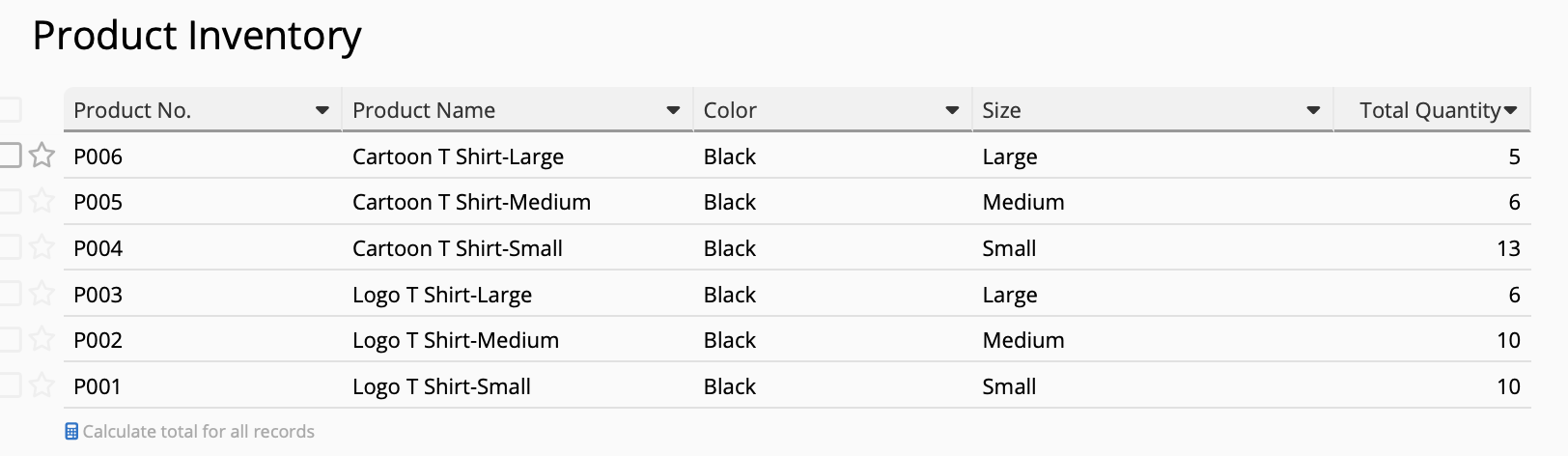

Let's say you've created a record for each design only, without further separating them by SKU. When filling out a sales order, you'll only be able to see information for the 2 designs, and the inventory number shown would be the quantity of all the sizes added together.

If you've designed a stock-deduction action button in this scenario, you can only deduct the stock quantity of "all the sizes added together," so you would still need to remember how many Small, Medium, and Large sizes of each shirt design was purchased and manually adjust the stock quantity balance for each size.

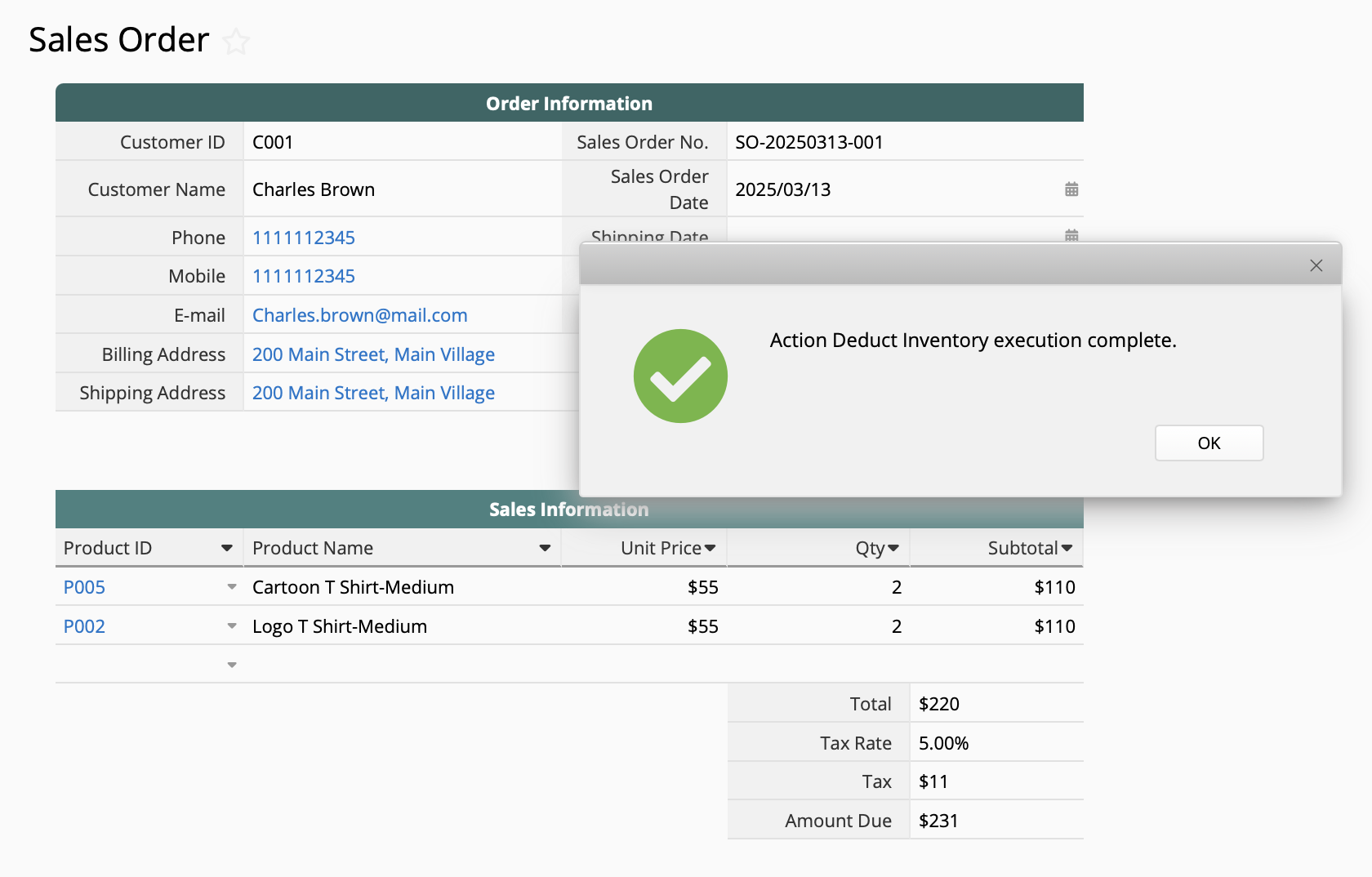

However, you'll be able to more accurately set up link and load and deduct outgoing inventory to get the remaining balances if each design and size are separated into independent records.

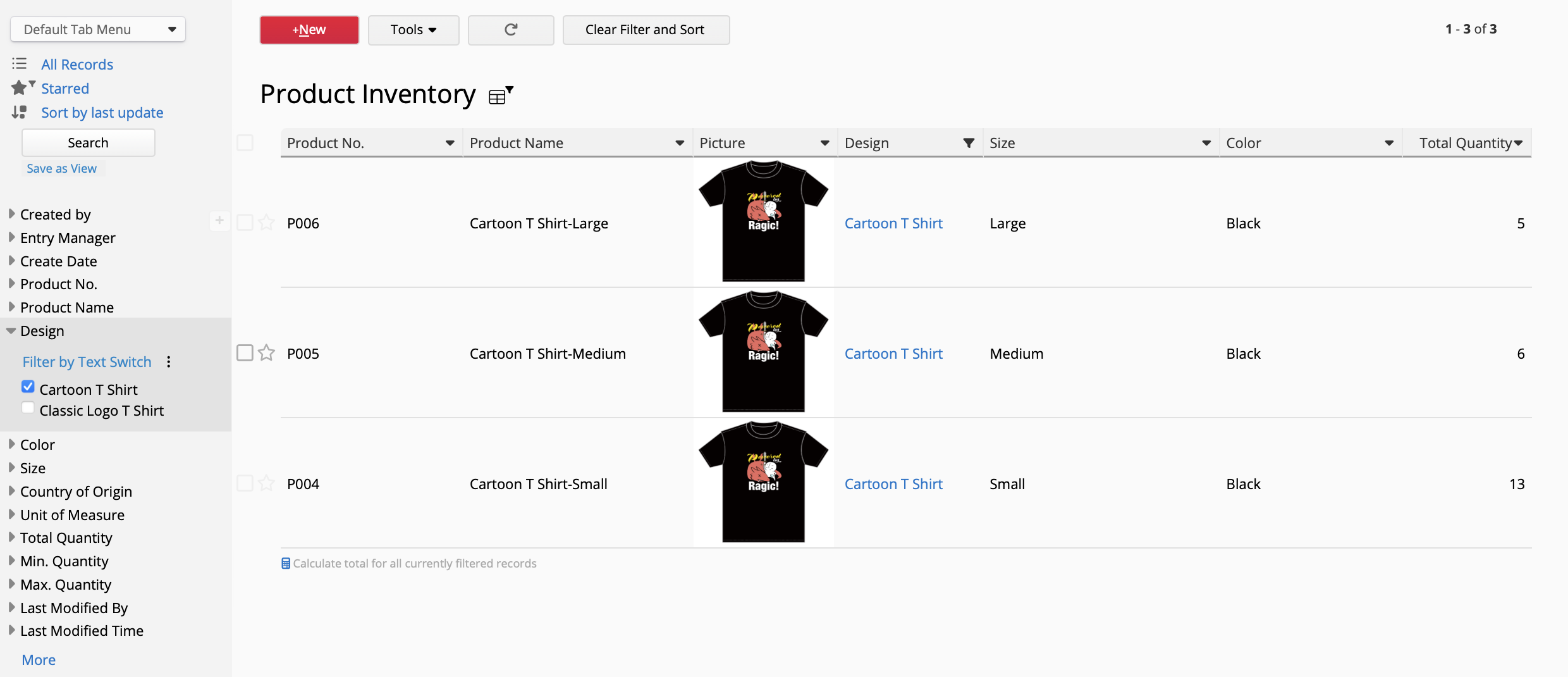

You can design your inventory sheet from scratch according to the principles above, or you can use Ragic's templates and make necessary adjustments. Taking the "Inventory" sheet of the Lite or Comprehensive Inventory templates for example, your listing page would look like this after separating the records:

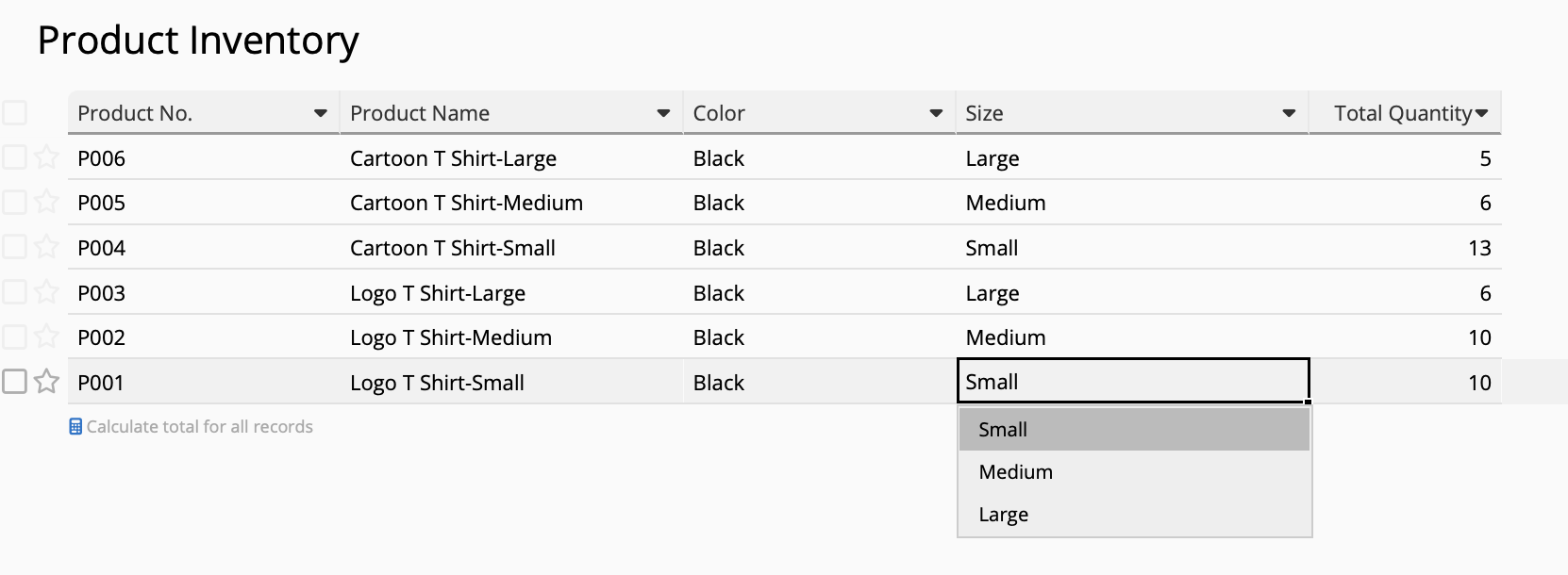

You can then properly manage inventory after separating the records, which include deducting outgoing stock and updating inventory balances. You can also consider making the following adjustments to make the detailed specifications (such as size and color) clearer:

You can add a selection field and record color and size in separate fields. This makes it easier to add new data, filter, and analyze inventory. (You can change the original "specification" field to "design" depending on your needs)

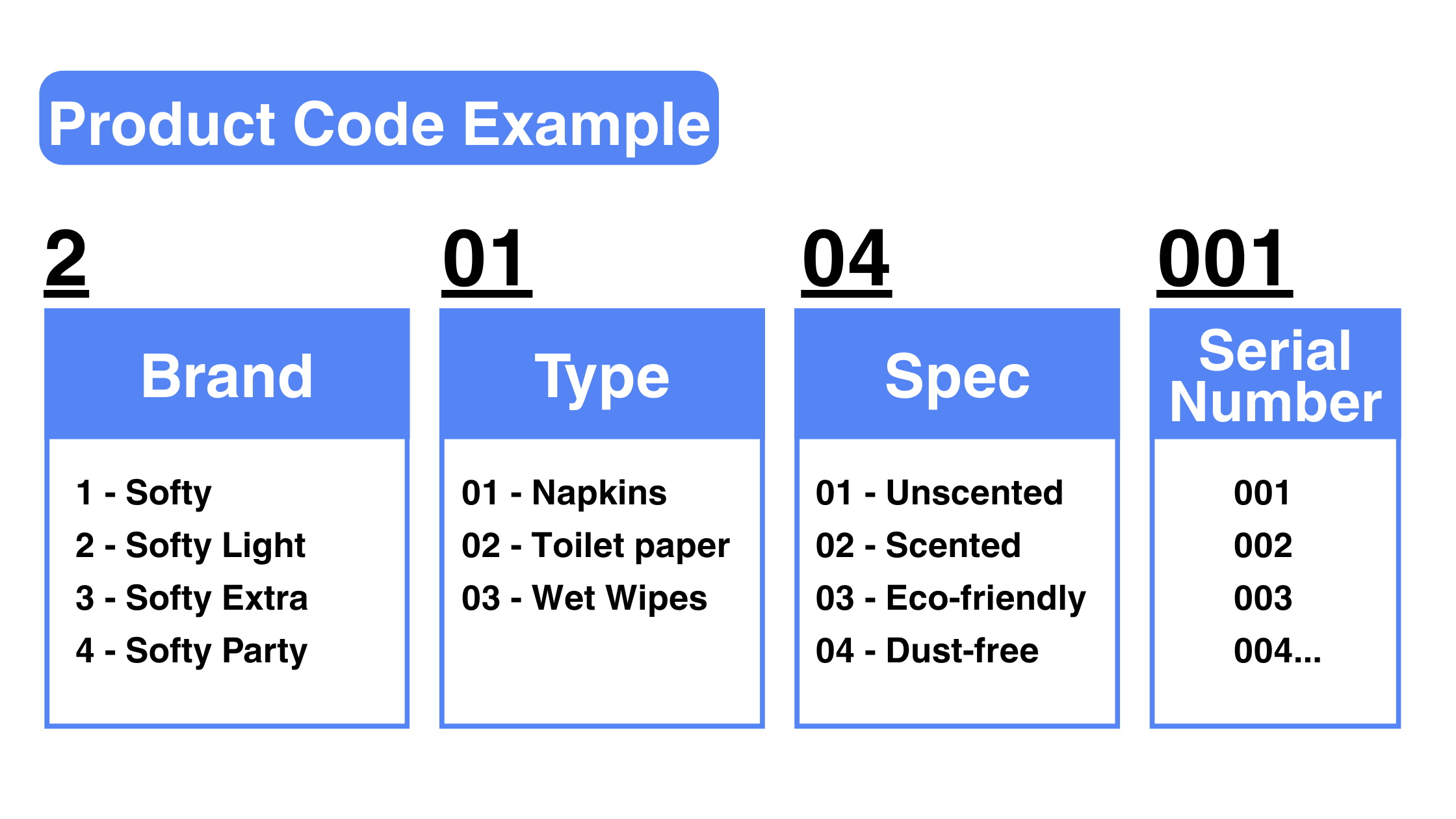

The product numbers in the template start with a "P," followed by a string of numbers by default. This method is simple to meet the needs of having various products. However, if you want to make the name, color, size, and other information clear and easily identifiable with just a glance of the product number, you can combine string formulas with unique settings to produce a useful number that can allow you to easily identify the product within a second.

Some people develop the misconception that separating products into different SKUs will lead to too much data and cause inconvenience when analyzing inventory. However, there are many ways Ragic can meet this need. The following methods demonstrate ways to quickly view the inventory quantity of a particular design:

Pros: No need to create additional reports and sheets

Cons: It may be troublesome to operate manually every time

You may directly filter the data from the listing page. For example, you can filter "design" by selecting "Classic logo," and all the different sizes for this design will be listed on your page. You can then use the total and summary to calculate the inventory balance available for the design.

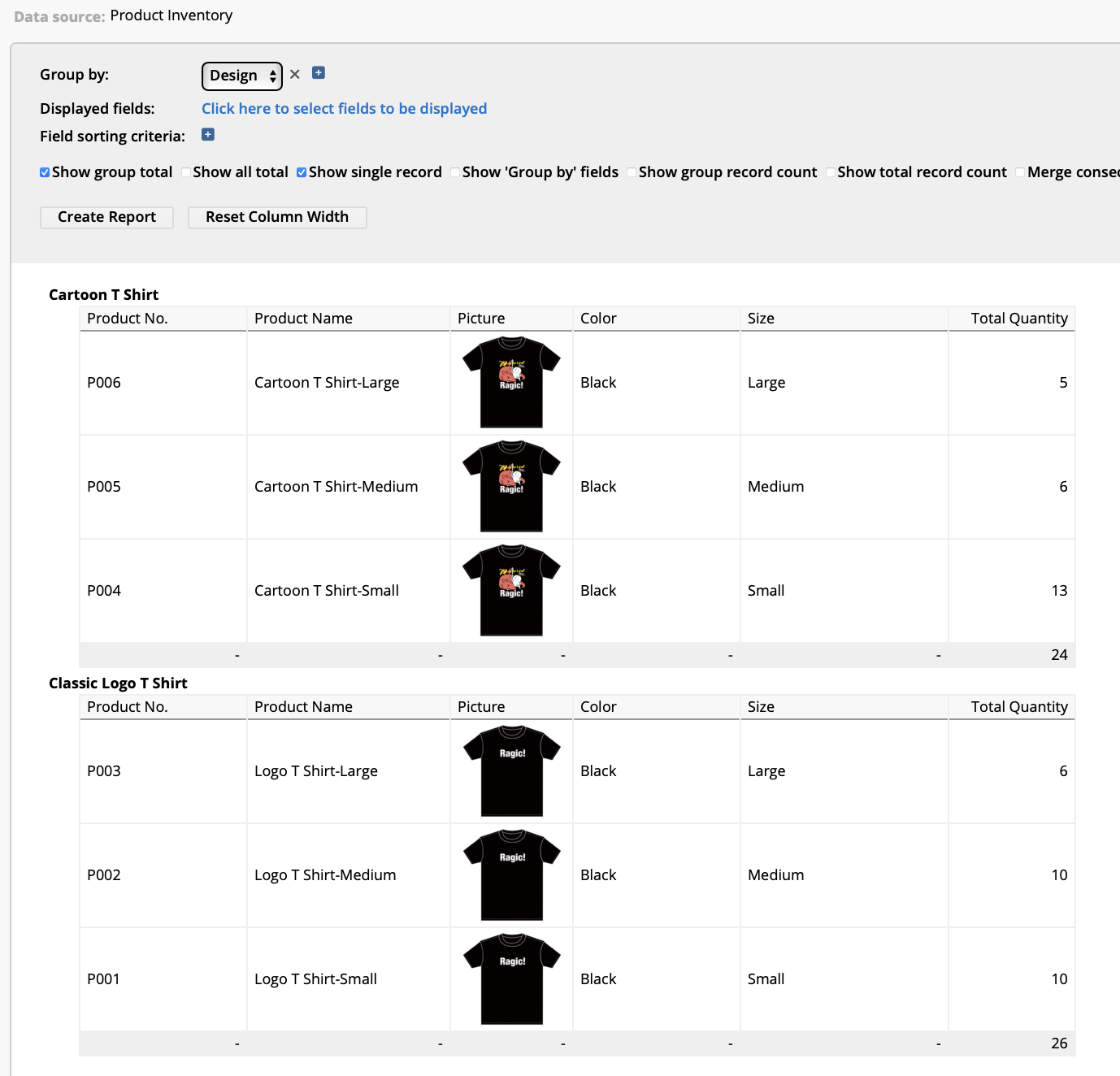

Pros: Simply click on the report to view the inventory status

Cons: Since all the designs will be grouped and listed on the same page, you may need to scroll up and down when searching for a particular design

If you find it troublesome to frequently filter and input designs when searching for data, we recommend using Grouping Reports. By setting the design field as the grouping field, the system will automatically help you classify them into different designs, listing the sizes and colors available, as well as the inventory quantity of each. After saving the report, you can check the inventory status at any time with just once click.

Pros: You can add more fields, store, and include more information needed for calculation and analysis

Cons: You'll need to design a new sheet

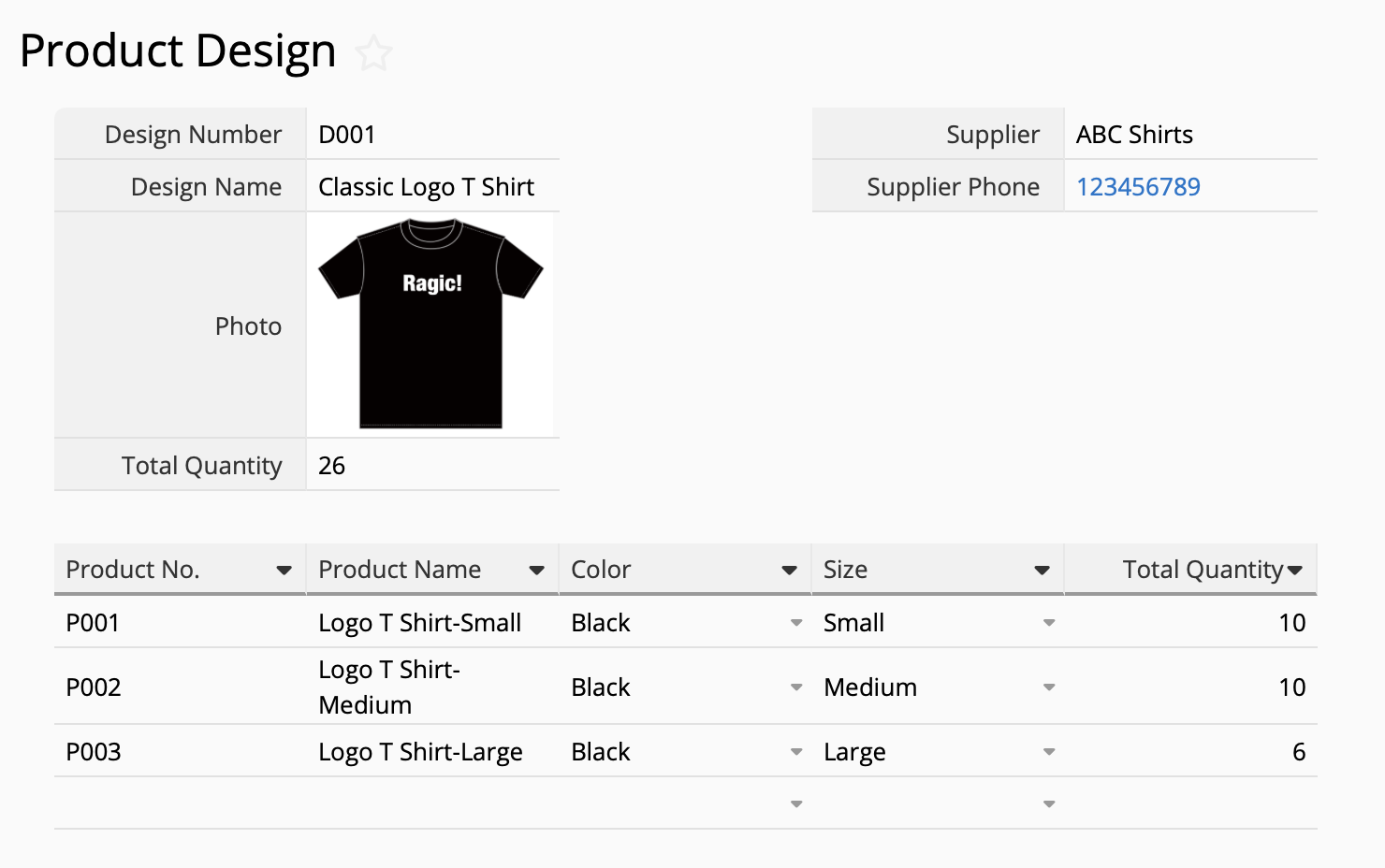

Filtering and grouping reports can only aggregate and list data. Hence, if you would like to present "design" as an independent data or record some additional information about the design (eg. Supplier name and phone number), you can directly create a Product Design sheet and use "link from other sheets" field to insert a reference subtable and summarize the inventory under each design.

Tips: If you would like to aggregate data by referencing a subtable, you would need to link the "design" field from the Product Design sheet to the "design" field in the "Product Inventory" sheet (the design field may be originally presented as a selection field and will need to be changed to the "Select from other sheets" field). The Product Design sheet must contain data of each design before it can be selected in the Product Inventory sheet and before they can be aggregated.